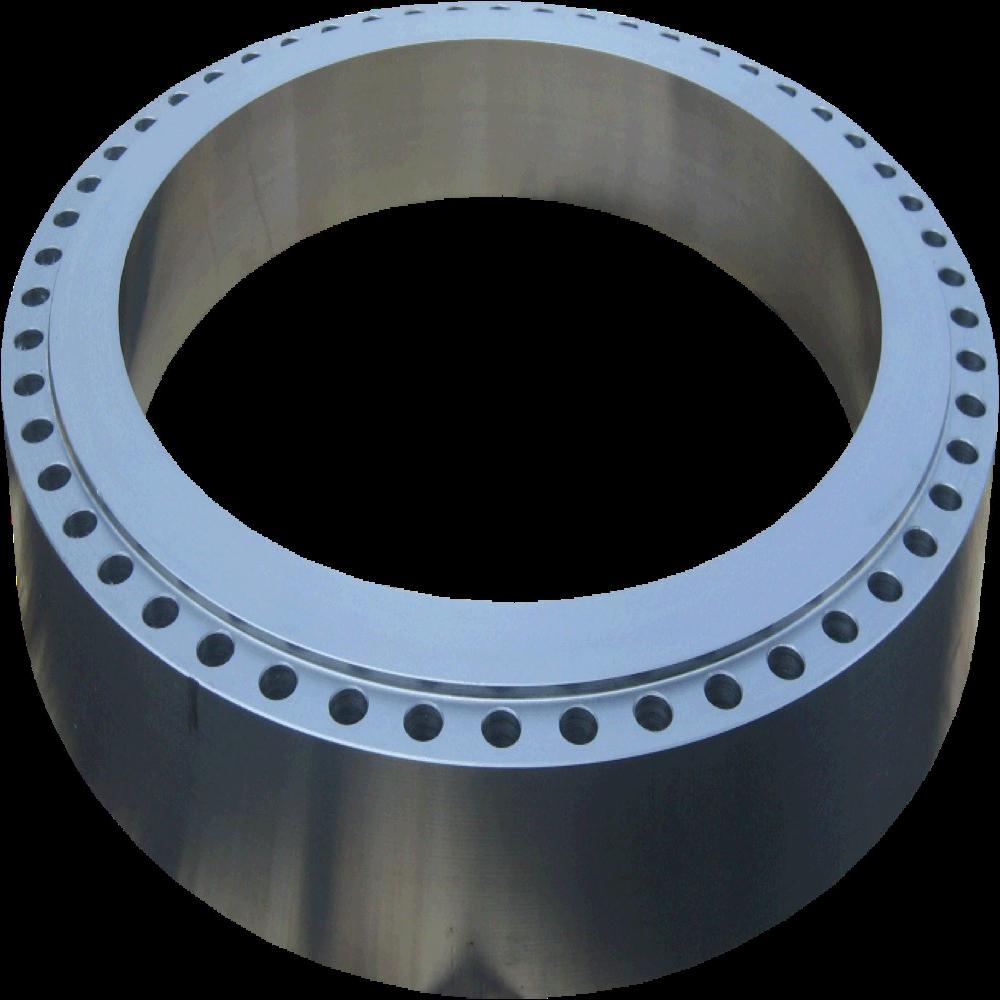

Forged flange

-

Payment

L/C(usance) , T/T

-

MOQ

500 ea

-

Supply Ability

100,000 ea per One-Time

-

Country of sale

Asia, Americas, Europe, World Wide

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

FTC

-

origin

Republic of Korea

-

Size(Capacity)

1/2"~96"

-

Condition

Forged

-

Material

A105, F304L, F316L

-

Function

pipe fitting

PRODUCT DESCRIPTION

1. SLIP-ON FLANGE

: it has a low hub because the pipe slips into the flange prior to weling. It is welded both inside and ourside to provide sufficient strength and prevent leakage. Slip-on flanges are all bored slightly larger than the OD of the matching pipe.

: it has a low hub because the pipe slips into the flange prior to weling. It is welded both inside and ourside to provide sufficient strength and prevent leakage. Slip-on flanges are all bored slightly larger than the OD of the matching pipe.

2. WELIDING NECK FLANGE

: it is normally referred to as the "hign hub" flanges. it is designed to transfer stresses to the pipe, thereby reducing high stress concentrations at the base of the flanges.

: it is normally referred to as the "hign hub" flanges. it is designed to transfer stresses to the pipe, thereby reducing high stress concentrations at the base of the flanges.

3. SOCKET WELDING FLANGE

: it is similar to a slip-on flange except it has a bore and a counterbore dimension. the counterbore is slightly lareger than the OD of the matching pipe. the diameter of the smaller bore is the same as the ID of the matching pipe.

: it is similar to a slip-on flange except it has a bore and a counterbore dimension. the counterbore is slightly lareger than the OD of the matching pipe. the diameter of the smaller bore is the same as the ID of the matching pipe.

4. THREADED(SCREWED) FLANGE

: it is similar to the slip-on flange, but the bore is threaded. it can be assembled without welding.

: it is similar to the slip-on flange, but the bore is threaded. it can be assembled without welding.

5. BLIND FLANGE

: it is a flange without a bore. it is used to close off the ends of a piping system and/or a pressure vessel opening.

: it is a flange without a bore. it is used to close off the ends of a piping system and/or a pressure vessel opening.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(usance)

- Telegraphic Transfer : T/T

- Name : KIM JONG OH

SHIPPING

Shipping from :

Republic of Korea

- 85 Mieumsandan 3-ro, Gangseo-gu, Busan (46744)

FELIX TECHNOLOGY CO., LTD.

The person in charge

Jong oh KimAddress

85 Mieumsandan 3-ro, Gangseo-gu, Busan (46744)

Introduction

. On the basis of excellent quality and service, we have been successfully supplying forged products and flanges as well to domestic and overseas Oil & Gas, Ship-building, Petrochemical & Power Plant fields.

And we have been continuously developing our management system for better technology innovation and improvement of competitiveness to be a leader in the foring fileds.

We, based on the haed office in Korea, have made investment in domestic as well as overseas such as a forging factory a branch in USA and etc, in order to provide exellent products with competitive prices and deliveries. We will try to serve our client with the best quality and satisfaction in return for their continuous interest and trust.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Forged flange

-

- Established :

- 1998-01-01

-

- Total Annual Revenue :

-

- Total Employees :

- 51~100 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 51~100 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- FELIX TECHNOLOGY CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

SUPPLIER BEST

- No Items