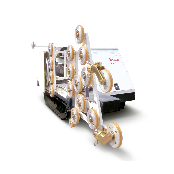

Multi-RobotSaw Equipment with wireless control capability

-

Payment

L/C(sight) , OT , T/T

-

MOQ

1 ea

-

Supply Ability

9,999,999 ea per One-Time

-

Supply Details

Customization

Negotiable

-

Country of sale

Americas, Europe, Middle East, World Wide, Asia

-

PRICE

-

FOB

Depend on quantity

-

CIF

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model Multi-RobotSaw Equipment with wireless control capEgun GCC

-

origin

Republic of Korea

-

Size(Capacity)

2600 mm (L) × 760 mm (W) × 1750 mm (H)

-

Function

Industrial cutting, crushing, gripping, and wire-saw operations for nuclear decommissioning and heav

-

Material

High-strength steel, industrial-grade alloy components, reinforced robotic arm structure

-

Color

Blue, Yellow, and Black (standard equipment colors)

-

Dimensions

Not applicable (mobile robotic equipment)

-

Weight

1850 kg

-

Style

Robotic cutting system with interchangeable attachments (wire saw, blade saw, gripper)

-

Expiry Date

Not applicable (durable industrial machinery)

-

Condition

New industrial equipment

-

Features

Wireless remote control, dual cutting mode (wire saw + blade saw), high-precision robotic manipulati

-

Gender

Not applicable

-

age-appropriate

Professional adult operators / certified industrial technicians

PRODUCT DESCRIPTION

Multi-RobotSaw Equipment with wireless control capability

The Multi-RobotSaw Equipment is a next-generation cutting system engineered for high-risk industrial environments such as nuclear power plant decommissioning, heavy structural demolition, and precision material removal. Unlike conventional excavator-based cutters, this equipment integrates a specialized robotic platform designed to deliver stable, fine-tuned, and highly controlled cutting performance. It is optimized for handling pipes, concrete structures, and metallic components that require both accuracy and substantial cutting force. The system performs both wire-saw cutting and wall-saw style blade cutting, enabling operators to use a single machine for a wide range of demolition tasks.

One of the core advantages of this product is its wireless remote control capability, allowing safe operation at a distance during high-radiation, confined-space, underwater-risk, or debris-hazard environments. The compact body and crawler-type mobility make it suitable for narrow reactor buildings, turbine halls, and industrial sites where conventional heavy equipment cannot enter. Its fine robotic arm movement provides a level of dexterity that greatly surpasses standard excavators, enabling gripping, clamping, cutting, and crushing operations with high precision.

The Multi-RobotSaw’s cutting module produces powerful output while maintaining stable feed control, making it ideal for thick pipes, reinforced concrete, embedded steel x-frames, and various nuclear-grade materials. The system is designed to reduce secondary waste, limit vibration transfer, and achieve a cleaner cutting surface—important factors in nuclear dismantlement and high-precision industrial work. Additionally, the platform supports interchangeable attachments, allowing operators to perform clamping, crushing, and wire-saw operations in one integrated solution.

One of the core advantages of this product is its wireless remote control capability, allowing safe operation at a distance during high-radiation, confined-space, underwater-risk, or debris-hazard environments. The compact body and crawler-type mobility make it suitable for narrow reactor buildings, turbine halls, and industrial sites where conventional heavy equipment cannot enter. Its fine robotic arm movement provides a level of dexterity that greatly surpasses standard excavators, enabling gripping, clamping, cutting, and crushing operations with high precision.

The Multi-RobotSaw’s cutting module produces powerful output while maintaining stable feed control, making it ideal for thick pipes, reinforced concrete, embedded steel x-frames, and various nuclear-grade materials. The system is designed to reduce secondary waste, limit vibration transfer, and achieve a cleaner cutting surface—important factors in nuclear dismantlement and high-precision industrial work. Additionally, the platform supports interchangeable attachments, allowing operators to perform clamping, crushing, and wire-saw operations in one integrated solution.

Product Features

Specialized equipment optimized for nuclear power plant structure cutting and heavy-duty industrial demolition

Performs both wire-saw and blade-saw operations with one machine

Highly precise robotic manipulation for cutting, crushing, gripping, and pipe removal

Enhanced safety using wireless remote control operation

Compact body suitable for confined industrial spaces

High-output cutting force for steel pipes, concrete structures, and high-strength materials

Performs both wire-saw and blade-saw operations with one machine

Highly precise robotic manipulation for cutting, crushing, gripping, and pipe removal

Enhanced safety using wireless remote control operation

Compact body suitable for confined industrial spaces

High-output cutting force for steel pipes, concrete structures, and high-strength materials

Product Effects & Applications

Improves safety by removing operators from hazardous environments

Reduces work time through multi-function cutting performance

Delivers excellent cutting accuracy with minimal structural vibration

Ideal for nuclear decommissioning, industrial dismantling, construction engineering, and heavy-material processing

Enables efficient handling of pipes, ducts, reactor components, and reinforced structures

Reduces work time through multi-function cutting performance

Delivers excellent cutting accuracy with minimal structural vibration

Ideal for nuclear decommissioning, industrial dismantling, construction engineering, and heavy-material processing

Enables efficient handling of pipes, ducts, reactor components, and reinforced structures

About Us

∙ Company Overview

Egun GCC, established in 2016, is Korea's leading nuclear decommissioning equipment manufacturer specializing in diamond wire saws, robotic cutting systems, and eco-friendly dust collection technologies with 31 patents and $1M exports to 8 countries.

∙ Factory Information

Our integrated facility in Gwangju-si, Gyeonggi Province features R&D labs, precision machining, and assembly lines meeting ISO 9001/14001 and CE certifications.

∙ Our Service

We provide precision concrete cutting for radioactive structures, remote-controlled robotic equipment minimizing radiation exposure, and advanced dust collection systems. Services include equipment rental, technical consulting, training, and maintenance support.

∙ Our Policy

We prioritize worker safety through automation, minimize environmental impact while maximizing resource recycling. As a certified climate tech company, we're committed to carbon neutrality and sustainable nuclear decommissioning.

Other Products

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : Chae Mun Lee

SHIPPING

Shipping from :

Republic of Korea

- 830-11 Docheok-ro Docheok-myeon, Gwangju-si, Gyeonggi-do (12817)

EGUN Co., Ltd.

The person in charge

Do-Eun LeeAddress

830-11 Docheok-ro Docheok-myeon, Gwangju-si, Gyeonggi-do (12817)

EGUN Co.,

EGUN Co., Ltd.

Introduction

Company Overview

Egun GCC, established in 2016, is Korea's leading nuclear decommissioning equipment manufacturer specializing in diamond wire saws, robotic cutting systems, and eco-friendly dust collection technologies with 31 patents and $1M exports to 8 countries.

Factory Information

Our integrated facility in Gwangju-si, Gyeonggi Province features R&D labs, precision machining, and assembly lines meeting ISO 9001/14001 and CE certifications.

Our Service

We provide precision concrete cutting for radioactive structures, remote-controlled robotic equipment minimizing radiation exposure, and advanced dust collection systems. Services include equipment rental, technical consulting, training, and maintenance support.

Our Policy

We prioritize worker safety through automation, minimize environmental impact while maximizing resource recycling. As a certified climate tech company, we're committed to carbon neutrality and sustainable nuclear decommissioning.

-

- Business Type :

- Manufacturer

-

- Main Product :

- saw machine, wire saw, floor saw

-

- Established :

- 2016-11-11

-

- Total Annual Revenue :

- 6 million to 10 billion (KRW)

-

- Total Employees :

- Less than 5

R&D CERTIFICATE

-

- KS Q ISO 9001:2015 / ISO 9001:2015

- SBCR.KR

- 2020.12.18

-

- CE Certificate

- EC Declaration of Conformity

- 2018

- 인증서보기

-

- KS I ISO 14001:2015 / ISO 14001:2015

- SBCR.KR

- 2021.06.25

- 인증서보기

-

- CE Certificate

- EC Declaration of Conformity

- 2019.12.20

- 인증서보기

-

- KS Q ISO 9001:2015 / ISO 9001:2015

- KOSRE

- 2023.12.08

- 인증서보기

-

- CE

- EC Declaration of Conformity

- 2019.12.20

- 인증서보기

-

- ISO 14001:2015

- KOSRE

- 2024.06.14

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 6 million to 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 158

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- EGUN Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★