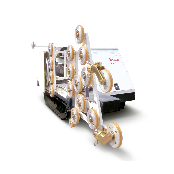

Heavy Duty Crawler Track Wire Saw Equipment

-

Payment

L/C(sight) , OT , T/T

-

MOQ

1 ea

-

Supply Ability

9,999,999 ea per One-Time

-

Supply Details

Customization

Negotiable

-

Country of sale

Americas, Europe, Middle East, World Wide, Asia

-

PRICE

-

FOB

Depend on quantity

-

CIF

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model ST-100EEgun GCC

-

origin

Republic of Korea

-

Size(Capacity)

Use (Application): Nuclear facility dismantling, industrial demolition, concrete structure cutting

-

Function

Concrete and metal cutting for nuclear decommissioning and demolition

-

Material

Steel frame body with protective cover

-

Color

Orange and gray

-

Dimensions

Industrial, nuclear decommissioning sites

-

Weight

2450 kg

-

Style

Tracked mobile cutting equipment

-

Expiry Date

Not applicable (durable industrial machinery)

-

Condition

New

-

Features

Full cover interior wire system for enhanced safety Radio remote control operation Water drainage sy

-

Gender

N/A

-

age-appropriate

N/A

-

Package Includes

Diesel engine 100HP, wire cutting system, crawler tracks, radio remote control, water drainage syste

PRODUCT DESCRIPTION

Heavy Duty Crawler Track Wire Saw Equipment

Daily Output & Performance:

The ST-100E achieves cutting speeds of up to 10-15 square meters per day depending on material thickness and density. Powered by a robust 100HP diesel engine, this equipment delivers consistent high-performance cutting for extended operational periods in demanding industrial environments.

Product Features

· Advanced Safety Design:

Full-cover interior wire system protects operators and minimizes debris exposure during cutting operations

· Remote Operation:

Radio remote control enables safe distance operation, crucial for hazardous nuclear decommissioning sites

· Superior Mobility:

Crawler track system (1570×2800×1750mm) provides excellent stability and maneuverability on uneven terrain

· Water Management:

Integrated drainage system effectively manages cooling water and reduces dust generation

· International Certification:

CE certified product meeting rigorous European safety and quality standards

· Compact Power:

2500kg weight optimized for transport while maintaining structural integrity

Product Efficacy

Specifically engineered for nuclear facility dismantling and heavy-duty industrial demolition, the ST-100E excels at precision cutting of reinforced concrete structures, thick metal components, and composite materials. The diamond wire cutting technology ensures clean cuts with minimal vibration, reducing structural stress on surrounding areas—critical for controlled decommissioning operations.

Technical Specifications

| Dimensions | 1570mm(W) × 2800mm(L) × 1750mm(H) |

| Weight | 2500kg |

| Power Source | Diesel Engine 100HP |

| Cutting Method | Diamond wire saw system |

| Control System | Radio remote control |

| Mobility | Tracked crawler system |

| Certification | CE certified |

| Origin | Republic of Korea |

Usage Method

· Site Preparation:

Position equipment on stable ground, ensure adequate water supply connection

· Remote Setup:

Establish radio control connection, verify signal strength and response

· Wire Installation:

Mount diamond wire saw according to cutting requirements and material specifications

· Water System Activation:

Engage cooling and dust suppression water system

· Cutting Operation:

Execute cutting via remote control from safe distance, monitor progress continuously

· Post-Operation:

Drain water system, perform equipment inspection and maintenance

Ideal Applications:

Nuclear power plant decommissioning, reactor vessel cutting, containment structure dismantling, industrial facility demolition, bridge demolition, concrete structure removal.

About Us

∙ Company Overview

Egun GCC, established in 2016, is Korea's leading nuclear decommissioning equipment manufacturer specializing in diamond wire saws, robotic cutting systems, and eco-friendly dust collection technologies with 31 patents and $1M exports to 8 countries.

∙ Factory Information

Our integrated facility in Gwangju-si, Gyeonggi Province features R&D labs, precision machining, and assembly lines meeting ISO 9001/14001 and CE certifications.

∙ Our Service

We provide precision concrete cutting for radioactive structures, remote-controlled robotic equipment minimizing radiation exposure, and advanced dust collection systems. Services include equipment rental, technical consulting, training, and maintenance support.

∙ Our Policy

We prioritize worker safety through automation, minimize environmental impact while maximizing resource recycling. As a certified climate tech company, we're committed to carbon neutrality and sustainable nuclear decommissioning.

Other Products

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : Chae Mun Lee

SHIPPING

Shipping from :

Republic of Korea

- 830-11 Docheok-ro Docheok-myeon, Gwangju-si, Gyeonggi-do (12817)

EGUN Co., Ltd.

The person in charge

Do-Eun LeeAddress

830-11 Docheok-ro Docheok-myeon, Gwangju-si, Gyeonggi-do (12817)

EGUN Co.,

EGUN Co., Ltd.

Introduction

Company Overview

Egun GCC, established in 2016, is Korea's leading nuclear decommissioning equipment manufacturer specializing in diamond wire saws, robotic cutting systems, and eco-friendly dust collection technologies with 31 patents and $1M exports to 8 countries.

Factory Information

Our integrated facility in Gwangju-si, Gyeonggi Province features R&D labs, precision machining, and assembly lines meeting ISO 9001/14001 and CE certifications.

Our Service

We provide precision concrete cutting for radioactive structures, remote-controlled robotic equipment minimizing radiation exposure, and advanced dust collection systems. Services include equipment rental, technical consulting, training, and maintenance support.

Our Policy

We prioritize worker safety through automation, minimize environmental impact while maximizing resource recycling. As a certified climate tech company, we're committed to carbon neutrality and sustainable nuclear decommissioning.

-

- Business Type :

- Manufacturer

-

- Main Product :

- saw machine, wire saw, floor saw

-

- Established :

- 2016-11-11

-

- Total Annual Revenue :

- 6 million to 10 billion (KRW)

-

- Total Employees :

- Less than 5

R&D CERTIFICATE

-

- KS Q ISO 9001:2015 / ISO 9001:2015

- SBCR.KR

- 2020.12.18

-

- CE Certificate

- EC Declaration of Conformity

- 2018

- 인증서보기

-

- KS I ISO 14001:2015 / ISO 14001:2015

- SBCR.KR

- 2021.06.25

- 인증서보기

-

- CE Certificate

- EC Declaration of Conformity

- 2019.12.20

- 인증서보기

-

- KS Q ISO 9001:2015 / ISO 9001:2015

- KOSRE

- 2023.12.08

- 인증서보기

-

- CE

- EC Declaration of Conformity

- 2019.12.20

- 인증서보기

-

- ISO 14001:2015

- KOSRE

- 2024.06.14

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 6 million to 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 158

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- EGUN Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★